PED Approved Socket Weld Tee Manufacturers in India.

India’s most leading and quality oriented Manufacturers, Stockist, and Suppliers of ASME B16.11 Forged Socket Weld Tee. We are offering market leading prices on ANSI/ASME B16.11 Socket Weld Tee Fittings from Mumbai, India.

We keep adequate stock of Forged Socket Weld Tee Pipe Fittings ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS3799 in all Dimensions to satisfy any small and large quantity orders from our valuable customers.

- What is a Socket Weld Tee?

- Socket Weld Tee Specifications

- ASME B16.11 Socket Weld Tee Materials & Grades

- ASME B16.11 Socket Weld Tee Manufacturing Standards

- ASME B16.11 Socket Weld Tee Types

- Why Choose M P Jain Tubing Solutions LLP?

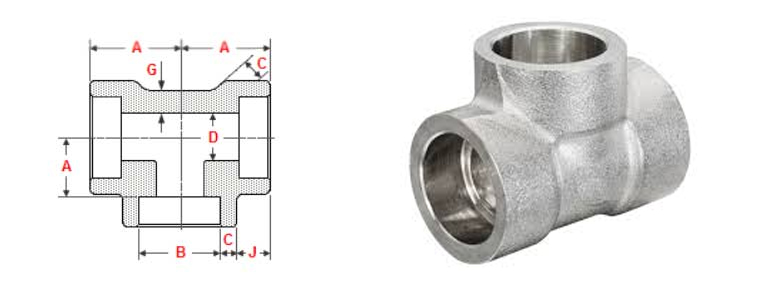

- ASME B16.11 Socket Weld Tee Dimensions

- B16.11 Socket weld Tee Fittings Applications

- Cities We Supply Socket weld Tee

- Countries We Supply Socket weld Tee

What is a Socket Weld Tee Pipe Fittings

Forged tees pipe fittings are used to branch a pipe at 90 degrees. Tees can be straight also called as equal tees or it can be reducing tees also called as unequal tees. Forged tees ASME B16.11 are available with socket weld or threaded connections (NPT or BSP). The dimensions of forged tees are covered by the MSS SP75 and the ASME B16.11 specifications.

ANSI B16.11 Socket Weld Tee Specifications

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/2″NB TO 4″NB IN |

| Pressure Class | 3000 LBS, 6000 LBS, 4500 LBS |

| Type | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| Value Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Production Grades: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

Forged Socket Weld Tee Materials & Grades

Stainless Steel Socket Weld Tee Pipe Fittings :

| Standard | ASTM / ASME A/SA 182 |

| Grade | F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L. |

Duplex & Super Duplex Socket Weld Tee Pipe Fittings :

| Standard | ASTM / ASME A/SA 182 |

| Grade | F44, F45, F51, F53, F55, F60, F61. |

Nickel Alloy Socket Weld Tee Pipe Fittings :

| Standard | ASTM / ASME SB 564 / 160 / 472 |

| Grade | UNS 2200 (NICKEL 200), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825), UNS 6600(INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 2201 (NICKEL 201), (ALLOY 20 / 20 CB 3) |

Copper Alloy Socket Weld Tee Pipe Fittings :

| Standard | ASTM / ASME SB 61 / 62 / 151 / 152. |

| Grade | UNS NO. C 92200, UNS NO. C 83600, UNS NO. 70600, 71500, C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30), UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200 |

Carbon Steel Socket Weld Tee Pipe Fittings :

| Standard | ASTMA 105/A694/ A350 LF3/A350 LF2. |

| Grade | F42, F46, F52, F56, F60, F65, F70 |

Alloy Steel Socket Weld Tee Pipe Fittings :

| Standard | ASTM A182 |

| Grade | F1, F5, F9, F11, F22, F91 |

Brass Socket Weld Tee Pipe Fittings :

| Grade | Brass CA 360, CA 345 and CA 377 / SAE J530, SAE J531 and ASA |

Forged Socket Weld Tee Manufacturing Standards

| ASTM A182 – ASME SA182 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings | ||

| ASME B16.9 | Factory-Made Wrought Buttwelding Fittings | ||

| ASME B16.11 | Forged Fittings, Socket – Welding and Threaded | ||

| MSS SP-43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications | ||

| MSS SP-95 | Swage(d) Nipples and Bull Plugs | ||

| BS3799 | Specification for Steel pipe fittings, screwed and Socket-welding for the petroleum industry |

Available Forged Socket Weld Tee Types

| Forged Socket weld Tees | Forged Socket weld Equal Tees |

| 150 lb. Socket Weld Reducing Tee | Socket weld Barrel Tee |

| ASME B16.11 Socket weld Lateral Tee | Tee 3000LB Socket Weld Fittings |

| Stainless Steel Straight Tee Suppliers | SS Unequal Forged Tees |

| ANSI B16.11 Forged Socket Weld Tee | BS3799 Forged Socket Weld Tees |

| Carbon Steel Socket weld Tee | High Pressure Socket weld Tee Manufacturer |

| ASTM A182 Socket weld Tees | Duplex Steel Socket weld Pipe Tee |

| Super Duplex Steel Socket weld Tee | Copper Nickel Socket weld Tee |

| High Nickel Alloy Forged Socket weld Tee | Hastelloy Socket weld Tee Pipe Fittings |

| Titanium Socket weld Tee | Inconel Socket weld Pipe Tee |

Why Choose M P Jain Tubing Solutions LLP?

- » M P Jain Tubing Solutions LLP is an ISO / OHSAS / PED Certified Stockist, Exporter, and Supplier of Forged Socket Weld Tee Pipe Fittings Manufactured with the finest quality of raw materials such as Stainless Steel, Duplex, Super Duplex, Nickel Alloys, Cupro Nickel, Alloy 20, Carbon Steel, SMO 256, Alloy Steel, Titanium, Brass, Hastelloy, Monel, Inconel, Incoloy etc. which results in High-Quality End Products.

- » We maintain huge stock that can fulfill any large requirements of our client and Since 1972 we are in this business and have experience of supplying and exporting of ASME B16.11 Forged Socket Weld Tees in different countries Including Qatar, Bahrain, Bangladesh, UAE, Iraq, Japan, Jordan, Kazakhstan, Lebanon, Myanmar, Oman, Philippines, Saudi Arabia, Sri Lanka, Thailand, Turkey, Uzbekistan, Yemen, etc. You are at the right place to buy it.

- » Our firm famed as the most trusted Socket Weld Forged Tee Manufacturers in Mumbai, India. The material used in the manufacturing process are of optimum quality that ensures notable features like high durability, strength, and resistivity to abrasion and corrosion.

- » We provide the material with all testing services before dispatch of the material.

- » Capable to manufacture ASME B16.11 Socket Weld Tee Pipe Fittings as per drawings.

- » These products are also checked stringently by quality analysts to ensure that defect free and best quality products to our honored clients.

- » In-house designing and testing facility and are also in process of adding more lines

- » All Products are designed and developed in accordance with the IQS(International Quality Standards).

- Optimum finish

- Precision-designed

- Lightweight

- Different sizes as per requirement

Socket Weld Tee Dimensions

Socket Weld Class 3000 Socket Weld Tee Dimensions NPS 1/2 to 4

Socket Weld Class 3000 Socket Weld Tee Dimensions NPS 1/2 to 4

| NPS | Socket Bore | Depth Socket | Bore dia |

|---|---|---|---|

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 4.90 4.25 |

3.90 | 19.5 |

| 1 | 5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 6.35 5.55 |

5.10 | 32 |

| 2 | 6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 8.75 7.65 |

7.00 | 41.5 |

| 3 | 9.50 8.30 |

7.60 | 57.5 |

| 4 | 10.70 9.35 |

8.55 | 66.5 |

| NPS | Socket Bore | Depth Socket | Bore dia |

|---|---|---|---|

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

| 1.1/4 | 42.80 42.55 |

13 | 30.2 28.7 |

| 1.1/2 | 48.90 48.65 |

13 | 34.7 33.2 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

| 1/2 | 5.95 5.20 |

4.80 | 19.5 |

| 3/4 | 6.95 6.05 |

5.55 | 22.5 |

| 1 | 7.90 6.95 |

6.35 | 27 |

| 1.1/4 | 7.90 6.95 |

6.35 | 32 |

| 1.1/2 | 8.90 7.80 |

7.15 | 38 |

| 2 | 10.90 9.50 |

8.75 | 41 |

- Dimensions are in millimeters unless otherwise indicated.

- Socket Bore (B) – Maximum and minimum dimensions.

- Bore Diameter (D) – Maximum and minimum dimensions.

- Socket wall thickness – (C) – Average of Socket wall thickness.

- Dimensional tolerances center to bottom of socket – (A)

NPS 1/2 and NPS 3/4 = +/- 1.5 mm

NPS 1 to NPS 2 = +/- 2 mm

NPS 2.1/2 to NPS 4 = +/- 2.5 mm

B16.11 Socket weld Tees Applications Industries

Chemicals Fertilizers Industries

Heat Exchanger

Instrumentation

Nuclear Thermal Industries

Oil Gas Industries

Pharmacy Surgical Industries

Refineries Petrochemicals

Water Gas Piping Systems

Cities We Export and Supply Socket Weld Tees

|

|

|

|

Countries We Export and Supply Socket Weld Tees

|

|

|

|