Authoritative ANSI B16.5 / ASME B16.47 Pipe Flanges Manufacturers in India.

As one of the leaders amongst Manufacturers, Stockist, and Exporters of Steel Pipe Flange Fittings, DIN Flanges, We are offering competitive prices in India on ANSI B16.5 Class 150 Flanges.

We keep adequate stock of Metal Flange Pipe Fittings, ANSI B16.5 Flanges, ASME B16.5 Flanges, ASME B16.47 Flanges, ANSI B16.47 Flanges in all Dimensions to satisfy any small and large quantity orders from our valuable customers.

- Pipe Flanges Specifications

- Pipe Flanges Materials and Grades

- Pipe Flanges Types

- Ready Stock of Pipe Flanges

- Why Choose us to Buy Pipe Flanges

- Pipe Flanges Price in India

- Pipe Flanges Dimensions

- Pipe Flanges Manufacturing Process

- Pipe Flanges Application Industries

- Cities We Export Pipe Flanges

- Countries We Export Pipe Flanges

PROFESSIONALLY MANAGED MANUFACTURING OF ANSI / ASME B16.5 / B16.47 FLANGES IN STAINLESS STEEL / DUPLEX STEEL / CARBON STEEL / ALLOY STEEL / HASTELLOY STEEL / MONEL STEEL / INCONEL STEEL / SUPER DUPLEX STEEL / INCOLOY STEEL / ALLOY 20 / 6% MOLY / COPPER NICKEL STEEL / NICKEL ALLOYS / ALUMINIUM / BRONZE / BRASS / CUPRO NICKEL / TITANIUM / LOW TEMPERATURE STEEL ETC.

Pipe Flanges Specifications

Types of Steel Pipe Flanges

Slip on Flange is essentially a ring that is placed over the pipe end, with the flange face extending from the end of the pipe by enough distance to apply a weld bead on the inside diameter. The OD of a slip-on flange is also welded on the back side of the Pipe flanges.

Explore More

A weld neck flange (also known as a high-hub flange and tapered hub flange) is a type of flange. There are two designs. The regular type is used with pipes. The long type is unsuitable for pipes and is used in process plant.

Explore More

A blind flange is a solid flange as shown in Picture. The purpose of these is to block off a section of pipe or a nozzle on a vessel that is not used. (A nozzle is typically a pipe coming out of a vessel and is usually flanged so it can be connected to valves or piping).

Explore More

Lap joint flanges use a stub end that is welded to the pipe. A ring flange fits loosely around the stub end, permitting easy flange alignment of the bolt holes. A lap joint flange is also called Van Stone or Stub Flange. The stub ends are available in three styles (Types A, B, and C) and two lengths (Short and Long).

Explore More

Threaded Flanges are also known as a screwed flange, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe. Threaded Flanges are mostly used in utility services such as air and water.

Explore More

Socket-weld pipe flanges are typically used on smaller sizes of high-pressure pipes. These pipe flanges are attached by inserting the pipe into the socket end and applying fillet weld around the top. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe.

Explore More

As the name suggests, Plate flange has a flat face. Flat face flanges are used when the counter-flanges are a flat face. This condition occurs mainly on connection to Cast Iron equipment, valves, and specialties. Full face gasket is used when a flat face flange is used.

Explore More

Ring joint type face flange has a specially designed grove in which metal gasket seat. This type of flange is used in high pressure and temperature services.

Explore More

Spectacle and line blind flanges are similar to a blind flange but different because they fit between two flanges. Spectacle blind gets their name from similarity to pair or eye-glasses. Once side of spectacle blind is fully closed for complete flow shuts off, whereas the other end is open for full flow. In this setup, the blinds can be rotated without having to take the system apart. It also gives visual confirmation if the line is open or close.

Explore More

The high hub blind flange is used to close ends of piping systems. It is a kind of round plate with no center hold but with all the proper bolt holes. This high hub blind flange is available in various sizes and materials and is used to provide positive closure on the ends of pipes, valves or equipment nozzles.

Explore More

Orifice Flanges are used with orifice meters for the purpose of measuring the flow rate of either liquids or gases in the respective pipeline. Pairs of pressure “Tappings”, mostly on 2 sides, directly opposite each other, are machined into the orifice flange.

Explore More

Reducing flanges are a specialty flange that is most often used on projects that require the fitting together of different sized pipes. There are several types of reducing flanges including weld-neck reducing flanges, slip-on reducing flanges and threaded reducing flanges.

Explore More

Square Flange made in accordance to JIS B2291 standard is a connecting piece that links JIS (Japanese Industrial Standards) nominal bore size pipes together and has a working pressure of up to 210kgf/cm2. This is equivalent to 210 Bar, or 21MPa. They are usually used in high-pressure systems such as hydraulic and steam lines for up to 3,000 PSI working pressure. There 3 types of Square flanges i.e. SHAB, SSAB, LSA.

Explore More

Groove & Tongue flange are referred to as either Groove & Tongue or Tongue. This is similar to a slip-on flange in outline, but the bore is Groove & Tongue, thus enabling assembly without welding. These threads are tapered in order to create a seal between the Groove & Tongue flange and the pipe as the tapers approach the same diameter. Groove & Tongue Flanges are used for special circumstances with their main advantage being that they can be attached to the pipe without welding.

Explore More

Long Neck Welding flanges (LWN) are similar to a standard Welding Neck flange, but the “Neck” is considerably longer. This type is often used as a nozzle for a barrel or column. In addition, there are the type LWN Heavy Barrel (HB) and the Equal LWN Barrel (E); they have a different shape and a thicker “Wall”.

Explore More

Spades and Ring Spacers are basically the same as Spectacle Blinds, except that both are not attached to each other. Spades and Spacers be applied in systems where maintenance is often not necessary, or in applications with large pipe sizes. Depending on the flange size and the Pressure Class, Spades can weigh hundreds of pounds. To prevent unnecessary weight to a flange connection usually will be chosen not for a Spectacle Blind, but for 2 separate parts.

Explore More

The Weldoflange and Nipoflange is a combination of a Welding Neck flange and a supposedly Weldolet or Nipolet. On the run pipe side, a nipoflange is designed like a weldolet. That means the branch connection on the run pipe side is a welding connection. On the other side, it has a flange connection. The flange connection can be designed according to customers requirements (acc. To DIN or ANSI).

Explore More

An Expander Flange is a type of welding neck pipe flange used to increase pipe size at the flange connection. Expander flanges are also known as a cost-effective alternative to using a separate reducer-welding neck flange combination. The expander flange is available in a range of sizes and materials.

Explore More

Contact for Stock Availability of Below Pipe Flanges

Blind Flanges

- » B16.5 Blind Flange 150lb

- » B16.5 Blind Flange 300lb

- » B16.5 Blind Flange 600lb

- » B16.5 Blind Flange 900lb

- » B16.5 Blind Flange 1500lb

- » B16.5 Blind Flange 2500lb

- » B16.47 Series B (API)Blind Flange 75lb

- » B16.47 Series B (API)Blind Flange 150lb

- » B16.47 Series B (API)Blind Flange 300lb

- » B16.47 Series B (API)Blind Flange 600lb

- » B16.47 Series B (API)Blind Flange 900lb

- » B16.47 Series A (MSS SP44) Blind Flange 150lb

- » B16.47 Series A (MSS SP44) Blind Flange 300lb

- » B16.47 Series A (MSS SP44) Blind lange 600lb

- » B16.47 Series A (MSS SP44) Blind Flange 900lb

Lap Joint Flanges

- » B16.5 Lap Joint 150lb Flange

- » B16.5 Lap Joint 300lb Flange

- » B16.5 Lap Joint 600lb Flange

- » B16.5 Lap Joint 900lb Flange

- » B16.5 Lap Joint 1500lb Flange

- » B16.5 Lap Joint 2500lb Flange

Socketweld Flanges

- » B16.5 Socket Welding 150lb Flange

- » B16.5 Socket Welding 300lb Flange

- » B16.5 Socket Welding 600lb Flange

- » B16.5 Socket Welding 1500lb Flange

Weld Neck Flanges

- » B16.5 Welding Neck Flange 150lb

- » B16.5 Welding Neck Flange 300lb

- » B16.5 Welding Neck Flange 600lb

- » B16.5 Welding Neck Flange 900lb

- » B16.5 Welding Neck Flange 1500lb

- » B16.5 Welding Neck Flange 2500lb

- » B16.47 Ser.B (API)Welding Neck Flange 75lb

- » B16.47 Ser.B (API)Welding Neck Flange 150lb

- » B16.47 Ser.B (API)Welding Neck Flange 300lb

- » B16.47 Ser.B (API)Welding Neck Flange 600lb

- » B16.47 Ser.B (API)Welding Neck Flange 900lb

- » B16.47 Ser.A (MSS SP44) Welding Neck Flange 150lb

- » B16.47 Ser.A (MSS SP44) Welding Neck Flange 300lb

- » B16.47 Ser.A (MSS SP44) Welding Neck Flange 600lb

- » B16.47 Ser.A (MSS SP44) Welding Neck Flange 900lb

Threaded Flanges

- » B16.5 Threaded 150lb Flange

- » B16.5 Threaded 300lb Flange

- » B16.5 Threaded 600lb Flange

- » B16.5 Threaded 900lb Flange

- » B16.5 Threaded 1500lb Flange

- » B16.5 Threaded 2500lb Flange

Slip-On-Flanges

- » B16.5 Class150 Slip on Flange

- » B16.5 Class300 Slip on Flange

- » B16.5 Class600 Slip on Flange

- » B16.5 Class900 Slip on Flange

- » B16.5 Class1500 Slip on Flange

- » B16.5 Class2500 Slip on Flange

High Hub Blinds Flanges

- » Class 150 HH Blind Flanges

- » Class 300 HH Blind Flanges

- » Class 600 HH Blind Flanges

JIS Flanges

- » 5 K Flanges

- » 10K Flanges

- » 16K Flanges

- » 30K Flanges

PN Flanges

- » PN 6 Flanges

- » PN 10 Flanges

- » PN 16 Flanges

- » PN 40 Flanges

- » 2576 Flanges

- » 2527 Flanges

SS Flanges/Stainless Steel Flange

- » 310 Flanges

- » 321 Flanges

- » 202 Flanges

- » 347 Flanges

- » 304 Flange

- » 316 Flanges

- » 316L Flanges

Duplex Flange

- » Duplex stainless Flanges

- » Super Duplex Stainless Flanges

- » S32750 Flanges

Flange Gaskets

Ring Flange

Orifice Flange

Reducing Threaded Flanges

Spectacle Blind Flanges

Flanges Bolts

ANSI Flange

ASME Flange

GOST Flange

DIN Flange

JIS/KS Flange

EN Flange

GB Flange

UNI / API Flange

BS Flange

- » FC Vacuum Flanges

- » Del-Seal CF Flanges

- » Industrial Flanges

- » Drilled Flanges

- » Dummy Flanges

- » CF Flanges

- » Orifice Assembly

- » End Flange

- » UNI Flanges

- » Pump Rings

- » ISO Flanges

- » Metal Flanges

- » MSS Flanges

- » ANSI B16.28

- » CUNI Flanges

- » Pipe Flanges

- » Flanges Exporters

- » Flanges Tolerance

- » A105 Flanges

- » A182 Flanges

- » A350 Flanges

- » AWWA Flanges

- » API Flanges

- » API 6A Flange

- » Forged Rings

- » Quality Flanges

- » MSS SP44 Flange

- » Piping Flanges

- » Series A Flanges

- » Series B Flanges

- » CS Flanges

- » custom flanges

- » KS Flanges

- » Light Weight Flanges

- » Alloy Flanges

- » P11 Flanges

- » P22 Flanges

- » BS Flanges

- » BS 4505 Flanges

- » MS Ring

- » JIS Flange

- » DIN Flanges

- » ANSI B16.9

- » ANSI Flanges

- » Flanges manufacturer

- » Mild Steel Flanges

- » MS Flanges

3293 Flanges

- » Long Neck Flanges

- » Orifice Flange

- » Slip-on (SORF) Flanges

- » WNRF Flanges

- » Raised Face Flanges

- » Spectacle Blind Flanges

- » Reducing Flanges

- » Plate Flanges

- » Blind Flanges

- » Flanges Bolts

- » Orifice Plate

- » Socket Flanges

- » Threaded Flanges

- » Forged Flanges

- » Lapped Flange

- » Block Flanges

- » Flange Gaskets

- » CZECH Flanges

- » Spectacle Flanges

- » Gost Flanges

- » Large Dia Flanges

- » Large Flanges

- » Circle Flanges

- » Valve Flanges

- » Reducing Threaded Flanges

- » Blank Flanges

- » Wire Seal Flanges

- » Slip on Flanges

- » Loose Flange

- » Steel Ring Flanges

- » Pump Flanges

- » RTJ Flanges

- » Welding Neck Flange

- » SORF Flange

- » HUB Blind Flanges

- » Socket weld Flanges

- » Galvanized Flanges

- » Taylor Flanges

- » Backup Flanges

- » Vacuum Flanges

- » F Table Flanges

- » D Table Flanges

- » E Table Flanges

- » Flanges Dimensional

- » 125 Class Flanges

- » 150 Flanges

- » 300 Flanges

- » 900 Flanges

- » 2500 Flanges

- » EN1092-1 Standard Flange

- » Australian AS 2129 Flange

- » Carbon Steel Flanges

- » Steel Flanges

Nickel Alloy Flanges / Non Ferrous Flanges

- » Nickel Flanges

- » Monel Flanges

- » Hastelloy C276 Flanges

- » Brass Flanges

- » Aluminium Flanges

- » Monel 400 Flanges

- » Incolloy 800 Flanges

- » Nickel 200 Flanges

- » Inconel 625 Flanges

- » Inconel 600 Flanges

- » Hastelloy Flanges

- » Inconel Flanges

- » Copper Flanges

- » Gunmetal Flanges

- » chrome steel Flanges

Why Choose M P Jain Tubing Solutions LLP

- » M P Jain Tubing Solutions LLP welcome small and large quantity orders and are capable of manufacture any type of Steel Flanges according to drawings provided by customers.

- » An ISO / OHSAS / PED Certified Stockist and Exporters of Industrial Steel Flanges Manufactured with the finest quality raw materials (Stainless Steel, Duplex, Super Duplex, Nickel Alloys, Cupro Nickel, Alloy 20, Carbon Steel, etc.) results in High-Quality End Products.

- » With the quality, we also guarantee On-Time Delivery of Steel Pipe Flanges. If clients have any query regarding purchased products they can chat with our support team live on a website (24/7 support service) or they can mail us on exports@mpjainco.com.

- » Our state-of-the-art infrastructure is located in the industrial hub, Mumbai India and we possess a team of highly qualified as well as experienced professionals. We continuously keep on upgrading our machinery to meet the challenges of fiercely competitive and ever-changing market demands.

- » We believe that along with Competitive Prices, the Quality performance of products and customer satisfaction are the basis for growth and success of our business. We tend to present innovative solutions and services to our customers.

- » Since 1972 we are in this business and Manufacturing Steel Flanges in different standards like ANSI, ASME, BS, DIN, API. Product Supplied by us are accepted by Client’s in various industries small basic industries such as Textile, Paper, Engineering, Sugar, Dairy, Cement to more complex such as Petrochemical, Oil & Gas, Power, Onshore & Offshore ETC. Our main export market is Bahrain, Bangladesh, Iraq, Japan, Jordan, Kazakhstan, Lebanon, Myanmar, Oman, Philippines, Qatar, Saudi Arabia, Sri Lanka, Thailand, Turkey, UAE, Uzbekistan etc.

Pipe Flanges Price List

Following is Steel Pipe Flanges price in India. This price range also depends on minimum order and might vary without any prior information. For more details contact us now and get Instant Quote.

Reference:alibaba

Pipe Flanges Dimensions:

| Nominal Pipe Size NPS (inches) | Class 150 Pipe Flanges | ||||

|---|---|---|---|---|---|

| Diameter of Flange (inches) | No. of Bolts | Diameter of Bolts (inches) | Diameter of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |

| Nominal Pipe Size NPS (inches) | Class 300 Pipe Flanges | ||||

|---|---|---|---|---|---|

| Diameter of Flange (inches) | No. of Bolts | Diameter of Bolts (inches) | Diameter of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-3/4 | 4 | 1/2 | 0.62 | 2-5/8 |

| 3/4 | 4-5/8 | 4 | 5/8 | 0.75 | 3-1/4 |

| 1 | 4-7/8 | 4 | 5/8 | 0.75 | 3-1/2 |

| 1-1/4 | 5-1/4 | 4 | 5/8 | 0.75 | 3-7/8 |

| 1-1/2 | 6-1/8 | 4 | 3/4 | 0.88 | 4-1/2 |

| 2 | 6-1/2 | 8 | 5/8 | 0.75 | 5 |

| 2-1/2 | 7-1/2 | 8 | 3/4 | 0.88 | 5-7/8 |

| 3 | 8-1/4 | 8 | 3/4 | 0.88 | 6-5/8 |

| 3-1/2 | 9 | 8 | 3/4 | 0.88 | 7-1/4 |

| 4 | 10 | 8 | 3/4 | 0.88 | 7-7/8 |

| 5 | 11 | 8 | 3/4 | 0.88 | 9-1/4 |

| 6 | 12-1/2 | 12 | 3/4 | 0.88 | 10-5/8 |

| 8 | 15 | 12 | 7/8 | 1 | 13 |

| 10 | 17-1/2 | 16 | 1 | 1.12 | 15-1/4 |

| 12 | 20-1/2 | 16 | 1-1/8 | 1.25 | 17-3/4 |

| 14 | 23 | 20 | 1-1/8 | 1.25 | 20-1/4 |

| 16 | 25-1/2 | 20 | 1-1/4 | 1.38 | 22-1/2 |

| 18 | 28 | 24 | 1-1/4 | 1.38 | 24-3/4 |

| 20 | 30-1/2 | 24 | 1-1/4 | 1.38 | 27 |

| 24 | 36 | 24 | 1-1/2 | 1.62 | 32 |

| Nominal Pipe Size NPS (inches) | Class 400 Pipe Flanges | ||||

|---|---|---|---|---|---|

| Diameter of Flange (inches) | No. of Bolts | Diameter of Bolts (inches) | Diameter of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-3/4 | 4 | 1/2 | 0.62 | 2-5/8 |

| 3/4 | 4-5/8 | 4 | 5/8 | 0.75 | 3-1/4 |

| 1 | 4-7/8 | 4 | 5/8 | 0.75 | 3-1/2 |

| 1-1/4 | 5-1/4 | 4 | 5/8 | 0.75 | 3-7/8 |

| 1-1/2 | 6-1/8 | 4 | 3/4 | 0.88 | 4-1/2 |

| 2 | 6-1/2 | 8 | 5/8 | 0.75 | 5 |

| 2-1/2 | 7-1/2 | 8 | 3/4 | 0.88 | 5-7/8 |

| 3 | 8-1/4 | 8 | 3/4 | 0.88 | 6-5/8 |

| 3-1/2 | 9 | 8 | 7/8 | 1 | 7-1/4 |

| 4 | 10 | 8 | 7/8 | 1 | 7-7/8 |

| 5 | 11 | 8 | 7/8 | 1 | 9-1/4 |

| 6 | 12-1/2 | 12 | 7/8 | 1 | 10-5/8 |

| 8 | 15 | 12 | 1 | 1.12 | 13 |

| 10 | 17-1/2 | 16 | 1-1/8 | 1.25 | 15-1/4 |

| 12 | 20-1/2 | 16 | 1-1/4 | 1.38 | 17-3/4 |

| 14 | 23 | 20 | 1-1/4 | 1.38 | 20-1/4 |

| 16 | 25-1/2 | 20 | 1-3/8 | 1.5 | 22-1/2 |

| 18 | 28 | 24 | 1-3/8 | 1.5 | 24-3/4 |

| 20 | 30-1/2 | 24 | 1-1/2 | 1.62 | 27 |

| 24 | 36 | 24 | 1-3/4 | 1.88 | 32 |

| Nominal Pipe Size NPS (inches) | Class 600 Pipe Flanges | ||||

|---|---|---|---|---|---|

| Diameter of Flange (inches) | No. of Bolts | Diameter of Bolts (inches) | Diameter of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-3/4 | 4 | 1/2 | 0.62 | 2-5/8 |

| 3/4 | 4-5/8 | 4 | 5/8 | 0.75 | 3-1/4 |

| 1 | 4-7/8 | 4 | 5/8 | 0.75 | 3-1/2 |

| 1-1/4 | 5-1/4 | 4 | 5/8 | 0.75 | 3-7/8 |

| 1-1/2 | 6-1/8 | 4 | 3/4 | 0.88 | 4-1/2 |

| 2 | 6-1/2 | 8 | 5/8 | 0.75 | 5 |

| 2-1/2 | 7-1/2 | 8 | 3/4 | 0.88 | 5-7/8 |

| 3 | 8-1/4 | 8 | 3/4 | 0.88 | 6-5/8 |

| 3-1/2 | 9 | 8 | 7/8 | 1 | 7-1/4 |

| 4 | 10-3/4 | 8 | 7/8 | 1 | 8-1/2 |

| 5 | 13 | 8 | 1 | 1.12 | 10-1/2 |

| 6 | 14 | 12 | 1 | 1.12 | 11-1/2 |

| 8 | 16-1/2 | 12 | 1-1/8 | 1.25 | 13-3/4 |

| 10 | 20 | 16 | 1-1/4 | 1.38 | 17 |

| 12 | 22 | 20 | 1-1/4 | 1.38 | 19-1/4 |

| 14 | 23-3/4 | 20 | 1-3/8 | 1.5 | 20-3/4 |

| 16 | 27 | 20 | 1-1/2 | 1.62 | 23-3/4 |

| 18 | 29-1/4 | 20 | 1-5/8 | 1.75 | 25-3/4 |

| 20 | 32 | 24 | 1-5/8 | 1.75 | 28-1/2 |

| 24 | 37 | 24 | 1-7/8 | 2 | 33 |

| Nominal Pipe Size NPS (inches) | Class 900 Pipe Flanges | ||||

|---|---|---|---|---|---|

| Diameter of Flange (inches) | No. of Bolts | Diameter of Bolts (inches) | Diameter of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/2 | 4-3/4 | 4 | 3/4 | 0.88 | 3-1/4 |

| 3/4 | 5-1/8 | 4 | 3/4 | 0.88 | 3-1/2 |

| 1 | 5-7/8 | 4 | 7/8 | 1 | 4 |

| 1-1/4 | 6-1/4 | 4 | 7/8 | 1 | 4-3/8 |

| 1-1/2 | 7 | 4 | 1 | 1.12 | 4-7/8 |

| 2 | 8-1/2 | 8 | 7/8 | 1 | 6-1/2 |

| 2-1/2 | 9-5/8 | 8 | 1 | 1.12 | 7-1/2 |

| 3 | 9-1/2 | 8 | 7/8 | 1 | 7-1/2 |

| 4 | 11-1/2 | 8 | 1-1/8 | 1.25 | 9-1/4 |

| 5 | 13-3/4 | 8 | 1-1/4 | 1.38 | 11 |

| 6 | 15 | 12 | 1-1/8 | 1.25 | 12-1/2 |

| 8 | 18-1/2 | 12 | 1-3/8 | 1.5 | 15-1/2 |

| 10 | 21-1/2 | 16 | 1-3/8 | 1.5 | 18-1/2 |

| 12 | 24 | 20 | 1-3/8 | 1.5 | 21 |

| 14 | 25-1/4 | 20 | 1-1/2 | 1.62 | 22 |

| 16 | 27-3/4 | 20 | 1-5/8 | 1.75 | 24-1/2 |

| 18 | 31 | 20 | 1-7/8 | 2 | 27 |

| 20 | 33-3/4 | 20 | 2 | 2.12 | 29-1/2 |

| 24 | 41 | 20 | 2-1/2 | 2.62 | 35-1/2 |

| Nominal Pipe Size NPS (inches) | Class 1500 Pipe Flanges | ||||

|---|---|---|---|---|---|

| Diameter of Flange (inches) | No. of Bolts | Diameter of Bolts (inches) | Diameter of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/2 | 4-3/4 | 4 | 3/4 | 0.88 | 3-1/4 |

| 3/4 | 5-1/8 | 4 | 3/4 | 0.88 | 3-1/2 |

| 1 | 5-7/8 | 4 | 7/8 | 1 | 4 |

| 1-1/4 | 6-1/4 | 4 | 7/8 | 1 | 4-3/8 |

| 1-1/2 | 7 | 4 | 1 | 1.12 | 4-7/8 |

| 2 | 8-1/2 | 8 | 7/8 | 1 | 6-1/2 |

| 2-1/2 | 9-5/8 | 8 | 1 | 1.12 | 7-1/2 |

| 3 | 10-1/2 | 8 | 1-1/8 | 1.25 | 8 |

| 4 | 12-1/4 | 8 | 1-1/4 | 1.38 | 9-1/2 |

| 5 | 14-3/4 | 8 | 1-1/2 | 1.62 | 11-1/2 |

| 6 | 15-1/2 | 12 | 1-3/8 | 1.5 | 12-1/2 |

| 8 | 19 | 12 | 1-5/8 | 1.75 | 15-1/2 |

| 10 | 23 | 12 | 1-7/8 | 2 | 19 |

| 12 | 26-1/2 | 16 | 2 | 2.12 | 22-1/2 |

| 14 | 29-1/2 | 16 | 2-1/4 | 2.38 | 25 |

| 16 | 32-1/2 | 16 | 2-1/2 | 2.62 | 27-3/4 |

| 18 | 36 | 16 | 2-3/4 | 2.88 | 30-1/2 |

| 20 | 38-3/4 | 16 | 3 | 3.12 | 32-3/4 |

| 24 | 46 | 16 | 3-1/2 | 3.62 | 39 |

| Nominal Pipe Size NPS (inches) | Class 2500 Pipe Flanges | ||||

|---|---|---|---|---|---|

| Diameter of Flange (inches) | No. of Bolts | Diameter of Bolts (inches) | Diameter of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/2 | 5-1/4 | 4 | 3/4 | 0.88 | 3-1/2 |

| 3/4 | 5-1/2 | 4 | 3/4 | 0.88 | 3-3/4 |

| 1 | 6-1/4 | 4 | 7/8 | 1 | 4-1/4 |

| 1-1/4 | 7-1/4 | 4 | 1 | 1.12 | 5-1/8 |

| 1-1/2 | 8 | 4 | 1-1/8 | 1.25 | 5-3/4 |

| 2 | 9-1/4 | 8 | 1 | 1.12 | 6-3/4 |

| 2-1/2 | 10-1/2 | 8 | 1-1/8 | 1.25 | 7-3/4 |

| 3 | 12 | 8 | 1-1/4 | 1.38 | 9 |

| 4 | 14 | 8 | 1-1/2 | 1.62 | 10-3/4 |

| 5 | 16-1/2 | 8 | 1-3/4 | 1.88 | 12-3/4 |

| 6 | 19 | 8 | 2 | 2.12 | 14-1/2 |

| 8 | 21-3/4 | 12 | 2 | 2.12 | 17-1/4 |

| 10 | 26-1/2 | 12 | 2-1/2 | 2.62 | 21-1/4 |

| 12 | 30 | 12 | 2-3/4 | 2.88 | 24-3/8 |

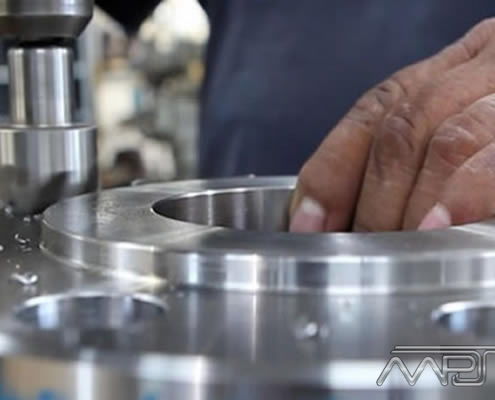

Manufacturing Process of Flanges

Raw Material

- » Raw Material Check

- » Quantity Check

- » Visual & Dimension Check

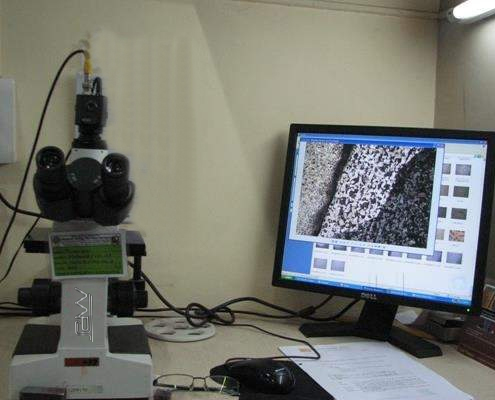

Material Inspection

- » Chemical Analysis Check

- » Preservation Analysis Certificate

Material Cutting

- » Weight Measuring

- » Cut Surface Check

- » Marking

Flange Forging

- » Material Grade Check

- » Weight Measuring

- » Temperature Control

Heat Treatment

- » Normalizing

- » Tempering, Q.T

- » Solution Treatment

- » Mechanical Test

Forging Rolling

- » Material Grade Check

- » Weight Measuring

- » Temperature Check

- » Dimension Check

Final Inspection

- » Dimension size inspect

- » Visual Test

- » Nondestructive Test

Rust Prevention

- » Preserve Check

- » Marking on the flange

- » Tectyl 506or Pickling or etc. Coating

Well Packing

- » Packing Spec. Check

- » Packing Inspection

- » Delivery

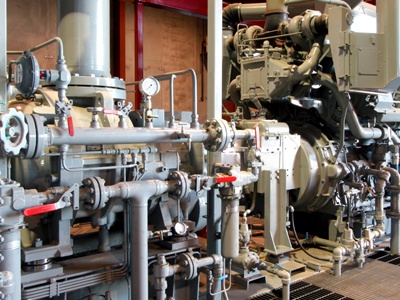

Pipe Flanges Application

Today M P Jain Tubing Solutions LLP is one of the leading manufacturer, stockists, and exporters of Pipe Flanges and supplying to various core industries like

Chemicals Fertilizers Industries

Heat Exchanger

Instrumentation

Nuclear Thermal Industries

Oil Gas Industries

Pharmacy Surgical Industries

Refineries Petrochemicals

Water Gas Piping Systems

Cities We Export Pipe Flanges

|

|

|

|

Countries We Export Pipe Flanges

|

|

|

|

Summary

Reviewer

M P Jain Tubing Solutions LLP

Review Date

Reviewed Item

Pipe Flanges

Author Rating