Authoritative UNI Flanges Manufacturers in India.

As one of the leaders amongst Manufacturers, Stockist, and Exporters of UNI Flanges, We are offering competitive prices in India on Flange UNI PN6/PN10/PN16/PN25/PN40.

We keep adequate stock of UNI Flanges in SS (Stainless Steel), Alloy Steel, Nickel Alloy, Carbon Steel, Inconel, Hastelloy, Copper Nickel, Duplex & Super Duplex, Alloy 20 in all Dimensions to satisfy any small and large quantity orders from our valuable customers.

- UNI Flanges Specifications

- UNI Flanges Materials and Grades

- Why Choose us to Buy UNI Flanges

- UNI Flanges Price in India

- UNI Flanges Dimensions

- UNI Flanges Available Types

- UNI Flanges Manufacturing Process

- UNI Flanges Application Industries

- Cities We Export UNI Flanges

- Countries We Export UNI Flanges

UNI Flanges Specifications

| Type | : | UNI Standard Flanges |

| Size | : | ½” (15 NB) to 48″ (1200NB), DN10 to DN3000. |

| Standard | : | ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820 |

| Class | : | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| DIN | : | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

| BS | : | BS4504 , BS4504, BS1560, BS10 |

| Pressure | : | PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160 |

| In Form | : | SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing, Spectacle, etc |

| Specialize | : | As per drawing |

| Coating/Surface Treatment | : | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Connection Type | : | Ring Type Joint, Lap-Joint Face, Raised Face, Flat Face, Large Male-Female, Small Male-Female, Large |

| Tongue & Groove, Small Tongue & Groove | ||

| Flange Face Type | : | Flat Face (FF), Raise Face (RF), Ring Joint (RJT) |

| Dimensions | : | ANSI B16.5, ANSI B16.47, Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Packing | : | No Fumigate or Fumigate Plywood/Wood Pallet or Case |

| Usage | : | Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc. |

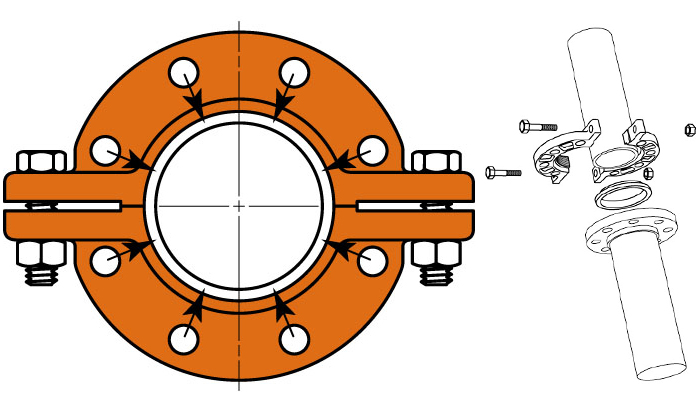

The UNI FLANGES Series 900 provides a power tight Rigid flanged connection, eliminating the need for solvent welding, tie rodding, harnessing and other forms of restraint.

Typical use of Uni-Flange restraint Include:

1) Adding flanges to PVC and Steel pipe

2) For Joining plain end pipe to valves, pumps and meter

UNI Flanges Materials & Grades

| Materials | : | Standard, Grades |

| Stainless Steel UNI Flanges | : | ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L |

| Carbon Steel UNI Flanges | : | ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, |

| F60, F65, F70 | ||

| Alloy Steel UNI Flanges | : | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Duplex Steel UNI Flanges | : | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| 6% Moly / Super Duplex UNI Flanges | : | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Low Temperature Steel UNI Flanges | : | ASTM A350 LF2, LF3, LF6 |

| High Yield UNI Flanges | : | ASTM A694 F42, F52, F60, F65, F70 |

| Nickel Alloys UNI Flanges | : | ASTM SB564, SB160, SB472, SB162 – Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |

| Copper Alloys UNI Flanges | : | ASTM SB 61 , SB62 , SB151 , SB152 – UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200 |

| Alloys UNI Flanges | : | ALLOY 20, ALLOY C, ALLOY C276, ALLOY B2 |

| Other Grade of UNI Flanges | : | Bronze, Brass, Cupro Nickel, Titanium, Inconel, Monel, Hastelloy, Mild Steel(MS) |

| SERIES | FLAT FLANGE (SLIP ON) | WELDING NECK | BLIND FLANGE |

|---|---|---|---|

| PN6 | UNI EN 1092-1 PN 6 (EX UNI 2276) | UNI EN 1092-1 PN 6 (EX UNI 2280) | UNI EN 1092-1 PN 6 (EX UNI 6091) |

| PN10 | UNI EN 1092-1 PN 10 (EX UNI 2277) | UNI EN 1092-1 PN 10 (EX UNI 2281) | UNI EN 1092-1 PN 10 (EX UNI 6092) |

| PN16 | UNI EN 1092-1 PN 16 (EX UNI 2278) | UNI EN 1092-1 PN 16 (EX UNI 2282) | UNI EN 1092-1 PN 16 (EX UNI 6093) |

| PN25 | UNI EN 1092-1 PN 25 (EX UNI 6083) | UNI EN 1092-1 PN 25 (EX UNI 2283) | UNI EN 1092-1 PN 25 (EX UNI 6094) |

| PN40 | UNI EN 1092-1 PN 40 (EX UNI 6084) | UNI EN 1092-1 PN 40 (EX UNI 2284) | UNI EN 1092-1 PN 40 (EX UNI 6095) |

Why Choose M P Jain Tubing Solutions LLP

- » M P Jain Tubing Solutions LLP welcome small and large quantity orders and are capable of manufacture UNI Flanges according to drawings provided by customers.

- » An ISO / OHSAS / PED Certified Stockist and Exporters of Flange UNI PN6/PN10/PN16/PN25/PN40. Manufactured with the finest quality raw materials (Stainless Steel, Duplex, Super Duplex, Nickel Alloys, Cupro Nickel, Alloy 20, Carbon Steel, etc.) results in High-Quality End Products.

- » With the quality, we also guarantee On-Time Delivery of ASME B16.5/B16.47 UNI Flanges. If clients have any query regarding purchased products they can chat with our support team live on a website (24/7 support service) or they can mail us on exports@mpjainco.com.

- » Our state-of-the-art infrastructure is located in the industrial hub, Mumbai India and we possess a team of highly qualified as well as experienced professionals. We continuously keep on upgrading our machinery to meet the challenges of fiercely competitive and ever-changing market demands.

- » We believe that along with Competitive Prices, the Quality performance of products and customer satisfaction are the basis for growth and success of our business. We tend to present innovative solutions and services to our customers.

- » Since 1972 we are in this business and Manufacturing UNI Standard Flanges. Product Supplied by us are accepted by Client’s in various industries small basic industries such as Textile, Paper, Engineering, Sugar, Dairy, Cement to more complex such as Petrochemical, Oil & Gas, Power, Onshore & Offshore ETC. Our main export market is Bahrain, Bangladesh, Iraq, Japan, Jordan, Kazakhstan, Lebanon, Myanmar, Oman, Philippines, Qatar, Saudi Arabia, Sri Lanka, Thailand, Turkey, UAE, Uzbekistan, Israel etc.

UNI Flanges Price List

Following is Flange UNI PN6/PN10/PN16/PN25/PN40 price in India. This price range also depends on minimum order and might vary without any prior information. For more details contact us now and get Instant Quote.

- » UNI Standard Stainless Steel Lapped Flange: USD $1.00-$100.00 / Piece

- » UNI FLANGE: USD $2.00-$90.00 / Piece

- » Stainless Steel Italy Standard Uni Plated Flange: USD $1.10-$10.00 / Piece

- » UNI 6093-67 FLANGE: USD $1.00-$800.00 / Piece

- » CS RST37.2 blind 6093-67 UNI flange: USD $0.99-$10.50 / Piece

- » UNI 2277 PN10 and BS4504 plate flange: USD $1.00-$8.00 / Piece

Reference:alibaba

UNI Flanges Dimensions:

UNI 2276 PN6 plate Flange Dimensions:

| ITALY STANDARD UNI 2276 PN6 PLATE FLANGE DIMENSIONS TABLE | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Directions for the designation | d1 | a | b | D | f | Holes | Screws | Weight* Kg |

||

| Rated Diameter |

External diameter of the pipe |

Nominal | Tolerance | |||||||

| 15 | 20 | 20,5 | +0,5 | 55 | 10 | 80 | 11 | 4 | M 10 | 0,34 |

| 21,3 | 22 | 0,33 | ||||||||

| 20 | 25 | 25,5 | 65 | 12 | 90 | 11 | 4 | M 10 | 0,51 | |

| 26,9 | 27,5 | 0,50 | ||||||||

| 25 | 30 | 30,5 | 75 | 12 | 100 | 11 | 4 | M 10 | 0,63 | |

| 33,7 | 34 | 0,61 | ||||||||

| 32 | 38 | 38,5 | 90 | 14 | 120 | 14 | 4 | M 12 | 1,09 | |

| 42,4 | 43 | 1,05 | ||||||||

| 40 | 44,5 | 45 | 100 | 14 | 130 | 14 | 4 | M 12 | 1,26 | |

| 48,3 | 49 | 1,23 | ||||||||

| 50 | 57 | 58 | 110 | 14 | 140 | 14 | 4 | M 12 | 1,38 | |

| 60,3 | 61,5 | 1,35 | ||||||||

| 65 | 76,1 | 77 | 130 | 14 | 160 | 14 | 4 | M 12 | 1,68 | |

| 80 | 88,9 | 90 | 150 | 16 | 190 | 18 | 4 | M 16 | 2,63 | |

| 100 | 108 | 109 | +1,0 | 170 | 16 | 210 | 18 | 4*** | M 16 | 3,05 |

| 114,3 | 115,5 | 2,92 | ||||||||

| 125 | 133 | 134,5 | 200 | 18 | 240 | 18 | 8 | M 16 | 4,11 | |

| 139,7 | 141 | 3,90 | ||||||||

| 150 | 159 | 160,5 | 225 | 20 | 265 | 18 | 8 | M 16 | 5,16 | |

| 168,3 | 170 | 4,78 | ||||||||

| 175 | 193,7 | 195,5 | 255 | 22 | 295 | 18 | 8 | M 16 | 6,27 | |

| 200 | 219,1 | 221 | 280 | 22 | 320 | 18 | 8 | M 16 | 6,91 | |

| 250 | 267 | 269 | 335 | 24 | 375 | 18 | 12 | M 16 | 9,53 | |

| 273 | 275 | 9,04 | ||||||||

| 300 | 323,9 | 326 | 395 | 24 | 440 | 22 | 12 | M 20 | 12,1 | |

| 350 | 355,6 | 358 | 445 | 26 | 490 | 22 | 12 | M 20 | 17,0 | |

| 368 | 370,5 | 15,6 | ||||||||

| 400 | 406,4 | 409 | +1,5 | 495 | 28 | 540 | 22 | 16 | M 20 | 20,1 |

| 419 | 422 | 18,3 | ||||||||

| 450 | 457,2 | 460,2 | ±5 | 550 | 28 | 595 | 22 | 16 | M 20 | 25,8 |

| 500 | 508 | 511 | 600 | 30 | 645 | 22 | 20 | M 20 | 30,0 | |

| 600 | 609,6 | 612,6 | 705 | 30 | 755 | 25 | 20 | M 22 | 37,9 | |

| 700 | 711,2 | 714,2 | 810 | 32 | 860 | 25 | 24 | M 22 | 47,9 | |

| 800 | 812,8 | 815,8 | 920 | 34 | 975 | 30 | 24 | M 27 | 62,9 | |

| 900 | 914,4 | 917,4 | 1020 | 36 | 1075 | 30 | 24 | M 27 | 74,6 | |

| 1000 | 1016 | 1019 | 1120 | 36 | 1175 | 30 | 28 | M 27 | 81,9 | |

| * | The weight is approximate and calculated on base 7.85 Kg/dm3. | |||||||||

| ** | Raw hole to be worked again according to the real external diameter of the pipe. | |||||||||

| *** | For oil piping the flange should have 8 holes. | |||||||||

UNI Flange Technical Data Chart Diameters & UNI Flange Summary Chart

The main products of UNI standards include:

(1) UNI2276 PN6, UNI2277 PN10, UNI2278 PN16, UNI6083 PN25, UNI6084 PN40, Plate Flange, Slip On Flange, C22.8, RST37.2, S235JR Carbon Steel, DN15-DN2000

(2) UNI6091 PN6, UNI6092 PN10, UNI6093 PN16, UNI6094 PN25, UNI6095 PN40, Blind Flange, Blank Flange, C22.8, RST37.2, S235JR Carbon Steel, DN15-DN2000.

(3) UNI2280 PN6, UNI2281 PN10, UNI2282 PN16, UNI2283 PN25, UNI2284 PN40, Weld Neck Flange, WNRF Flange, C22.8, RST37.2, S235JR Carbon Steel, DN15-DN1000.

(4) UNI2253 PN6, UNI2254 PN16, Threaded Flange, THR Flange, Screwed Flange, C22.8, RST37.2, S235JR Carbon Steel, DN15-DN150.

(5) UNI6088 PN6, UNI6089 PN10, UNI6090 PN16, Loose Flange, Lapped Flange, C22.8, RST37.2, S235JR Carbon Steel, DN15-DN1000.

| Description | Rated Pressure / Presión Nominal / Nenndruck (in bar) (1 bar = 14.5 psi) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2.5 | 6 | 10 | 16 | 25 | 40 | 64 | 100 | 160 | 250 | 320 | 400 | |

| DIN | |||||||||||||

| Blind Flanges | 6091 | 6092 | 6093 | 6094 | 6095 | 6096 | 6097 | 6098 | 6099 | ||||

| Flat flange for welding (slip-on) | 2276 | 2277 | 2278 | 6083 | 6084 | ||||||||

| Welding neck flanges | 2280 | 2281 | 2282 | 2283 | 2284 | 2285 | 2286 | ||||||

| Lapped flanges, Plain collars | 6088 | 6089 | 6090 | ||||||||||

| Loose flanges and rings for welding | |||||||||||||

| Loose flanges and rings with neck for welding | |||||||||||||

| Oval plain threaded flanges | |||||||||||||

| Oval flanges, with neck threaded | |||||||||||||

| Threaded flanges with neck | 2253 | 2254 | |||||||||||

| Long neck welding flanges | |||||||||||||

| Hubbed slip-on flanges for welding | |||||||||||||

UNI 2276 PN6 PLATE FLANGE DIMENSION

| ITALIAN STANDARDS UNI 2276 PLATE FLANGE PN 6 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Directions for the designation | d1 | a | b | D | f | Holes | Screws | Weight* Kg |

||

| Rated Diameter |

External diameter of the pipe |

Nominal | Tolerance | |||||||

| 15 | 20 | 20,5 | +0,5 | 55 | 10 | 80 | 11 | 4 | M 10 | 0,34 |

| 21,3 | 22 | 0,33 | ||||||||

| 20 | 25 | 25,5 | 65 | 12 | 90 | 11 | 4 | M 10 | 0,51 | |

| 26,9 | 27,5 | 0,50 | ||||||||

| 25 | 30 | 30,5 | 75 | 12 | 100 | 11 | 4 | M 10 | 0,63 | |

| 33,7 | 34 | 0,61 | ||||||||

| 32 | 38 | 38,5 | 90 | 14 | 120 | 14 | 4 | M 12 | 1,09 | |

| 42,4 | 43 | 1,05 | ||||||||

| 40 | 44,5 | 45 | 100 | 14 | 130 | 14 | 4 | M 12 | 1,26 | |

| 48,3 | 49 | 1,23 | ||||||||

| 50 | 57 | 58 | 110 | 14 | 140 | 14 | 4 | M 12 | 1,38 | |

| 60,3 | 61,5 | 1,35 | ||||||||

| 65 | 76,1 | 77 | 130 | 14 | 160 | 14 | 4 | M 12 | 1,68 | |

| 80 | 88,9 | 90 | 150 | 16 | 190 | 18 | 4 | M 16 | 2,63 | |

| 100 | 108 | 109 | +1,0 | 170 | 16 | 210 | 18 | 4*** | M 16 | 3,05 |

| 114,3 | 115,5 | 2,92 | ||||||||

| 125 | 133 | 134,5 | 200 | 18 | 240 | 18 | 8 | M 16 | 4,11 | |

| 139,7 | 141 | 3,90 | ||||||||

| 150 | 159 | 160,5 | 225 | 20 | 265 | 18 | 8 | M 16 | 5,16 | |

| 168,3 | 170 | 4,78 | ||||||||

| 175 | 193,7 | 195,5 | 255 | 22 | 295 | 18 | 8 | M 16 | 6,27 | |

| 200 | 219,1 | 221 | 280 | 22 | 320 | 18 | 8 | M 16 | 6,91 | |

| 250 | 267 | 269 | 335 | 24 | 375 | 18 | 12 | M 16 | 9,53 | |

| 273 | 275 | 9,04 | ||||||||

| 300 | 323,9 | 326 | 395 | 24 | 440 | 22 | 12 | M 20 | 12,1 | |

| 350 | 355,6 | 358 | 445 | 26 | 490 | 22 | 12 | M 20 | 17,0 | |

| 368 | 370,5 | 15,6 | ||||||||

| 400 | 406,4 | 409 | +1,5 | 495 | 28 | 540 | 22 | 16 | M 20 | 20,1 |

| 419 | 422 | 18,3 | ||||||||

| 450 | 457,2 | 460,2 | ±5 | 550 | 28 | 595 | 22 | 16 | M 20 | 25,8 |

| 500 | 508 | 511 | 600 | 30 | 645 | 22 | 20 | M 20 | 30,0 | |

| 600 | 609,6 | 612,6 | 705 | 30 | 755 | 25 | 20 | M 22 | 37,9 | |

| 700 | 711,2 | 714,2 | 810 | 32 | 860 | 25 | 24 | M 22 | 47,9 | |

| 800 | 812,8 | 815,8 | 920 | 34 | 975 | 30 | 24 | M 27 | 62,9 | |

| 900 | 914,4 | 917,4 | 1020 | 36 | 1075 | 30 | 24 | M 27 | 74,6 | |

| 1000 | 1016 | 1019 | 1120 | 36 | 1175 | 30 | 28 | M 27 | 81,9 | |

The weight is approximate and calculated on base 7.85 Kg/dm3

Raw hole to be worked again according to the real external diameter of the pipe

For oil piping the flange should have 8 holes O.D. = outside diameter PCD = bolt circle diameter PN = nominal pressure in bars

Note: (1 bar = 14.5 psi = 0.1 MPa = 100 KPa = 1.02 Kgf/cm²)

UNI Flanges Available Types

Our Specialization in Manufacturing Below UNI Flanges

|

|

|

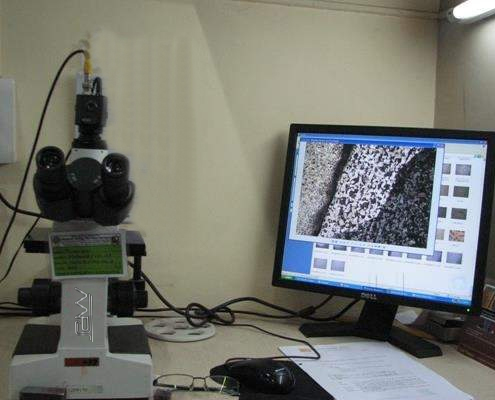

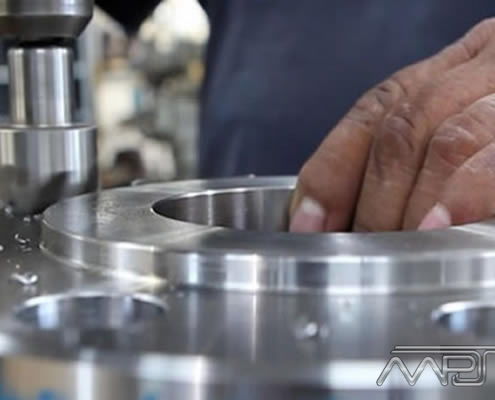

Manufacturing Process of UNI Flanges

We have Skilled staff to maintain the quality of products throughout the manufacturing process from selection of raw material to processing, marking, packaging, storage, and transportation. Our Flange UNI PN6/PN10/PN16/PN25/PN40 are 100% inspected before being packed and dispatched & all our materials are tested to International standards. Sometimes we also accept Third Party Inspection appointed by our clients.

Raw Material

- » Raw Material Check

- » Quantity Check

- » Visual & Dimension Check

Material Inspection

- » Chemical Analysis Check

- » Preservation Analysis Certificate

Material Cutting

- » Weight Measuring

- » Cut Surface Check

- » Marking

Flange Forging

- » Material Grade Check

- » Weight Measuring

- » Temperature Control

Heat Treatment

- » Normalizing

- » Tempering, Q.T

- » Solution Treatment

- » Mechanical Test

Forging Rolling

- » Material Grade Check

- » Weight Measuring

- » Temperature Check

- » Dimension Check

Final Inspection

- » Dimension size inspect

- » Visual Test

- » Nondestructive Test

Rust Prevention

- » Preserve Check

- » Marking on the flange

- » Tectyl 506or Pickling or etc. Coating

Well Packing

- » Packing Spec. Check

- » Packing Inspection

- » Delivery

UNI Flanges Applications & Uses

Today M P Jain Tubing Solutions LLP is one of the leading manufacturer, stockists, and exporters of UNI Standard Flanges and supplying to various core industries like

Chemicals Fertilizers Industries

Heat Exchanger

Instrumentation

Nuclear Thermal Industries

Oil Gas Industries

Pharmacy Surgical Industries

Refineries Petrochemicals

Water Gas Piping Systems

Cities We Export UNI Flanges

|

|

|

|

Countries We Export UNI Flanges

|

|

|

|